Saddle Stitch

Hand-sewn saddle stitch with 1 mm thick waxed thread: advantages over

Machine Stitching

When it comes to creating high-quality leather accessories, not only the choice of material matters, but also the stitching technique. One of the oldest and most respected methods is the hand-sewn saddle stitch, especially when done with thick 1 mm waxed thread. Unlike machine stitching used in mass production, the hand-sewn stitch represents durability and craftsmanship. Let’s explore what makes this technique unique and why it stands out compared to machine stitching.

What is Hand-Sewn Saddle Stitch?

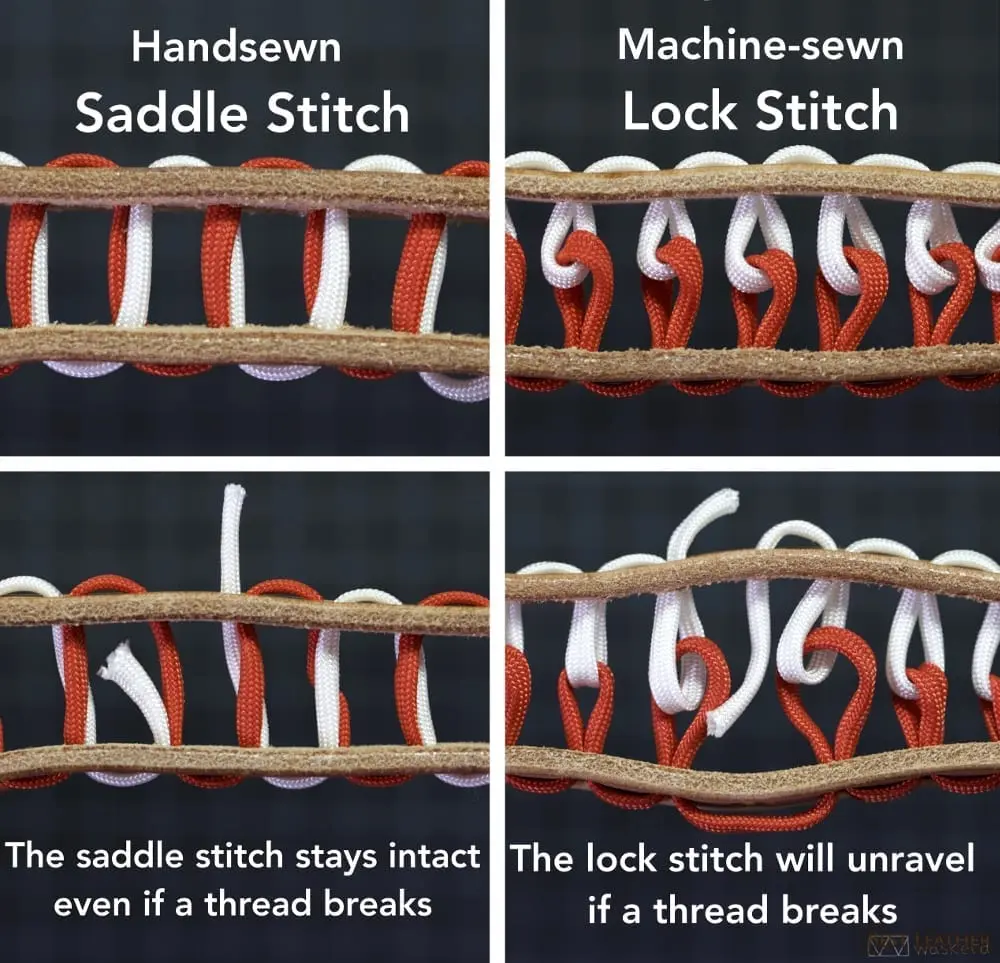

The saddle stitch is a traditional hand-sewing technique used to create strong seams in leather goods. It is renowned for its durability and reliability, making it popular among artisans crafting belts, wallets, sheaths, and other leather items. The process involves using two needles that pass through the same holes from opposite sides of the material. This creates a strong interlocking stitch that won't unravel even if one side of the thread breaks.

Benefits of Using 1 mm Thick Waxed Thread

Strength and Durability

The thick 1 mm waxed thread provides significantly greater strength compared to the thinner threads used in machine stitching. The waxing makes the thread smoother and more resistant to wear, while protecting it from moisture and dirt. Stitches made with such thread last for decades, retaining their quality over time.

Easy Repair

One of the key advantages of the saddle stitch is its ease of repair. If one part of the seam gets damaged (e.g., if the thread breaks), the piece will not lose its structural integrity, as each stitch is locked individually. On the other hand, machine stitching tends to unravel entirely if the thread breaks.

Aesthetic Appeal

A hand-sewn stitch with thick thread gives leather goods a unique and more rugged appearance. Each stitch is visible, adding a handcrafted touch that is highly valued by those who appreciate exclusive accessories. The thick thread makes the stitch stand out, adding textural contrast to the smooth leather surface.

Time-Consuming Process

Hand-stitching takes much more time and effort compared to machine stitching. Each hole is made manually, and the sewing process with two needles is more labor-intensive. This makes products with hand-sewn stitches more expensive but also more valuable for collectors and those who appreciate quality craftsmanship.

Machine Stitching

Differences from Machine Stitching

1. Stitch Construction

Machine stitching uses a single needle with one thread that loops through the fabric and locks on the underside. In contrast, saddle stitching involves two threads, each passing through the same hole, creating interlocking stitches on both sides. This not only makes the stitch more aesthetically pleasing but also exponentially stronger.

2. Resistance to Tension

Due to the interlocking stitches, the saddle stitch can withstand much higher mechanical loads. While machine stitching can be tight, it does not possess the same resistance to tearing, as it relies on a single thread and loop mechanism.

The hand-sewn saddle stitch represents meticulousness, attention to detail, and mastery. Unlike machine stitching, which is a mass-production method, the hand stitch is unique in every product. Using thick waxed thread further emphasizes the premium nature of the finished item, making it not only visually appealing but also incredibly durable.